cycle track construction

India’s cities are rapidly embracing smart infrastructure, and cycle tracks are becoming central to urban development plans. Designed to promote healthier lifestyles and greener mobility, cycle tracks are being installed in parks, public roadsides, educational campuses, smart cities, and residential areas. But while the concept of building these tracks is well understood, the real challenge lies in creating tracks that last long, stay safe, and perform well across all seasons.

This is where synthetic flooring—particularly acrylic-based systems—proves to be the most effective solution. In this article, we explore why synthetic flooring is ideal for cycle tracks, what benefits it offers over traditional materials, and how it supports cost-effective, long-term cycle track construction in Indian conditions.

Understanding the Purpose of a Cycle Track

Before choosing materials, it’s important to define what a cycle track needs to achieve. It’s not just a strip of pavement—it’s a dedicated space that must:

- Offer smooth and safe passage for riders of all ages

- Withstand high-frequency use

- Handle extreme heat, moisture, and dust

- Remain easy to maintain for city planners or community managers

These demands call for a material that is weather-resistant, low-maintenance, and designed for consistent performance under varied usage—precisely what synthetic cycle track materials offer.

The Problem with Traditional Flooring Choices

In many Indian cities, cycle paths are often laid with basic concrete, asphalt, or interlocking tiles. While these may be readily available and inexpensive, they bring several issues:

- Asphalt softens and cracks under high heat, especially in North and Central India.

- Concrete can be too hard, leading to discomfort during long rides and frequent surface cracks.

- Tiles become uneven over time, posing trip hazards and discomfort.

- Water stagnation and slippery surfaces make them dangerous during the monsoon.

Most of these problems lead to either increased accidents, user dissatisfaction, or costly repairs. Synthetic flooring offers a much more sustainable and safe alternative.

What Is Synthetic Flooring?

Synthetic cycle track flooring refers to man-made surface materials, usually composed of acrylic-based or polyurethane compounds. When applied in multiple layers over a prepared base, they create a seamless, weatherproof, and visually appealing cycle track surface.

In India, the most widely used synthetic option for cycle tracks is acrylic coating. This material is already used extensively in sports infrastructure like tennis courts, basketball courts, and running tracks—and its transition into cycle track projects has proven extremely effective.

Benefits of Using Acrylic Synthetic Flooring for Cycle Tracks

Let’s break down why acrylic cycle track flooring is ideal for Indian environments and usage conditions:

1. All-Weather Durability

Acrylic surfaces are formulated to resist UV radiation, moisture, and temperature extremes. Unlike asphalt that melts in the sun or tiles that crack in cold, acrylic stays stable year-round. It also dries quickly after rains, reducing downtime and avoiding slippery conditions.

2. Smooth, Joint-Friendly Riding Experience

The seamless finish of synthetic flooring ensures a smoother ride. Cyclists feel less vibration, face fewer bumps, and maintain better control—especially important for children or casual riders. Additionally, the even texture reduces wear and tear on bicycles.

3. Low Maintenance Requirements

Once installed, acrylic cycle track flooring requires only minimal maintenance. There’s no need for daily cleaning or expensive equipment. Regular sweeping and occasional surface washing are sufficient to keep it looking new for years. This is a huge advantage for municipalities or societies with limited upkeep budgets.

4. Safety and Traction

Acrylic finishes offer slip-resistant surfaces that maintain grip even in humid or light rainy conditions. This reduces the risk of accidents and allows year-round usability of the track—ideal for India’s unpredictable climate.

5. Custom Design and Branding Flexibility

Colors, logos, and lane markings can be added during the top coating phase, making the tracks visually appealing and easier to navigate. In public or corporate zones, these customizations help reinforce identity and branding while adding a premium touch.

Where Can Acrylic Cycle Tracks Be Installed?

Thanks to its flexible application, synthetic flooring can be installed in a wide variety of settings. These include:

- Public fitness tracks in parks or alongside roads

- Educational institutions looking to promote student wellness

- Smart cities as part of integrated transport infrastructure

- Gated communities and societies offering cycling loops

- Corporate parks encouraging employee health programs

- Tourist zones or beachfronts with scenic routes

Wherever safety, low maintenance, and visual appeal are needed, outdoor cycle track surface systems made from acrylic are the perfect fit.

Cost-Effectiveness Over Time

While the upfront cost of synthetic flooring may be higher than simple asphalt, the lifetime value of acrylic systems is significantly greater. Because they last longer, require fewer repairs, and reduce maintenance costs, they offer a better return on investment for developers and municipalities.

Add to that the reduction in accidents and increased user satisfaction, and it’s easy to see why more planners are turning to synthetic solutions for cycle track construction.

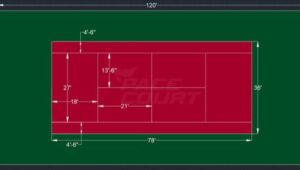

Key Components of an Acrylic Cycle Track System

A complete acrylic system includes:

- Base surface – Usually concrete or asphalt

- Primer coat – Binds the synthetic layer to the base

- Resurfacer layer – Levels the surface and fills small cracks

- Color coats – High-quality acrylic coatings with anti-skid texture

- Line markings – Directional arrows, lane guides, or branding

Optional cushion coats can be added for comfort in high-end projects or training-focused tracks.

Planning and Execution Tips

To get the most out of synthetic flooring, keep these tips in mind:

- Ensure proper base preparation with adequate slope for drainage

- Choose certified materials tested for Indian weather

- Avoid over-layering which can increase thickness and change ride feel

- Use contrasting colors for lane divisions and safe zones

- Work with experienced installers to avoid common errors

Working with a trusted supplier can make a significant difference in ensuring material compatibility, system performance, and longevity.

Conclusion

In the growing landscape of India’s urban development, cycle tracks are more than just a visual statement—they’re essential for sustainability, safety, and public well-being. Choosing the right flooring material is what turns a good cycle track into a great one.

Synthetic cycle track materials, especially acrylic-based systems, check all the right boxes: they’re durable, safe, visually appealing, easy to maintain, and long-lasting. For any city planner, architect, or developer seeking reliable infrastructure, acrylic flooring delivers unmatched results.

SLT Sports is a leading supplier of certified cycle track flooring systems across India. With climate-ready solutions, expert guidance, and quality assurance, SLT Sports supports the construction of smart, sustainable, and rider-friendly tracks that can shape the future of urban transport.